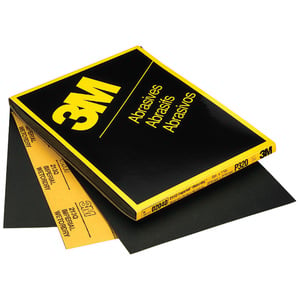

A 3M original, Wetordry™ abrasive sheets satisfy a wide range of sanding needs.

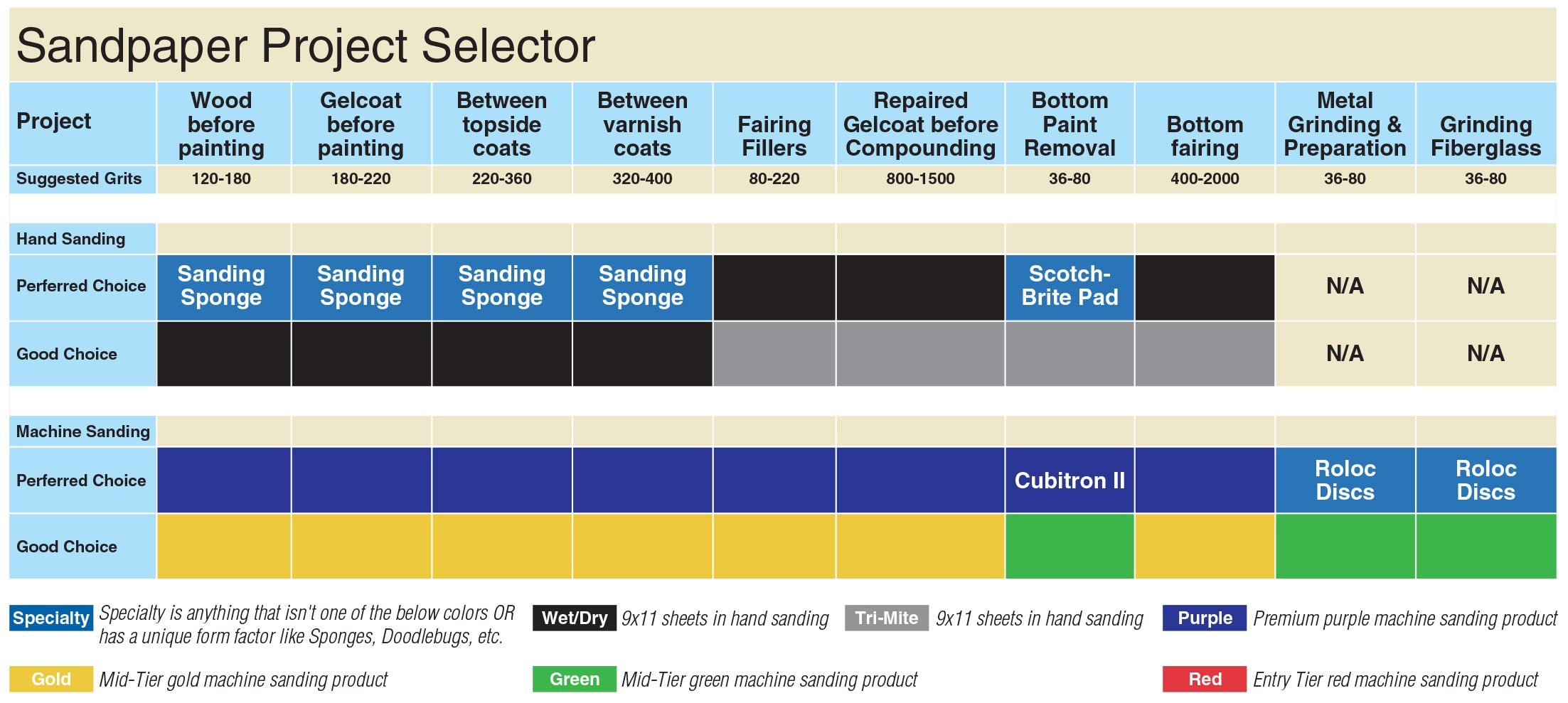

In the past, selecting sandpaper wasn’t complicated, but in recent years new choices have emerged. Beyond their long-standing line of Wetordry™; and Tri-M-ite Fre-Cut™ sandpaper sheets, 3M (our primary supplier for sanding abrasives) offers sanding products in a range of grades to meet the needs of casual do-it-yourselfers and demanding professionals alike. Recent additions to our abrasives lineup include a variety of sanding sponges and pads—which have proven their worth in many sanding tasks. Relatively recent arrivals also include 3M purple machine sanding sheets and discs. With so many choices, and the prevalence of machine sanding, folks need help selecting the best products for the job.

Aluminum oxide or silicon carbide?

The majority of sanding sheets and discs that we offer utilize aluminum oxide or silicon carbide as the abrasive. For most dry sanding projects, aluminum oxide sandpaper is best. For wet sanding, (or dry if you wish) use silicon carbide. Most of the sanding discs that we offer use various grades of aluminum oxide as the abrasive. Wetordry™ abrasive sheets by 3M are silicon carbide.

Stikit™ and Hookit™

Stikit™ and Hookit™ are 3M proprietary terms that refer to the attachment method for sandpaper sheets and discs. Stikit™ abrasives have a pressure sensitive adhesive (PSA) backing. Use requires a compatible disc pad, which we offer in several diameters. Hookit™ sanding products offer the greatest convenience, since they attach via a hook-and-loop backing which permits ultra-fast disc and sheet switch outs. Hookit™ sanding discs must also be used with a compatible disc pad.

Color Coding of Sanding Sheets and Discs

We offer 3M machine sanding sheets and discs in four different colors: Red, Green, Gold and Purple.

Red Sanding Sheets and Discs—Good

3M Red Abrasives are entry-level products offered at the lowest possible cost. Red discs are offered in standard (no holes) or dust-free (with holes) configuration in grits ranging from 40 up to 1500, which enables use for a wide range of stripping, sanding and finishing projects. For fairing and shaping operations, Sticket™ Red “Long and Skinny” rectangular sheets are available in a width to fit 3M’s Hookit Hand File Board or their . 3M rates their Red abrasives as “Good”.

Green Sanding Sheets and Discs—Better

“Long and Skinny” sheets for use with a fairing board.

The 3M Green Corp™ machine sanding sheets and discs that we offer range from 24 up to 80 grit. Most have an “E” or “D” weight backing, which makes these discs best for coarse operations such as stripping paint. Discs are offered in 5”, 6” and 8” diameters with a choice of either Stikit™ or Hookit™ attachment methods. For faring and shaping operations, Sticket™ Green “Long and Skinny” rectangular sheets are available in a choice of widths to fit 3M’s Hand File Board or Hookit™ Marine Fairing Board. 3M rates their Green Corp™ abrasives as “Better”.

Gold Sanding Sheets and Discs—Better

The gold sanding discs that we offer have been a mainstay of machine sanding for many years. They offer a good compromise between cost and performance, are available with a choice of Stikit™ or Hookit™ attachment methods, in a wide range of grits, and in dust-free or no-hole configuration. 3M rates their Gold abrasives as “Better”.

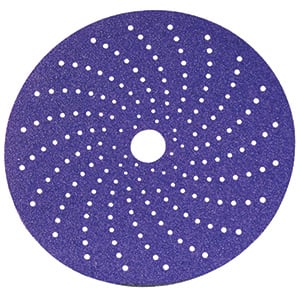

Purple Sanding Sheets and Discs—Best

3M Purple Sheets and Discs are precision abrasive products designed for fast cut and consistent finish. Because they sand faster you can get more done in a shorter amount of time. They are also designed to last longer than the Gold, Red and Green abrasives described above. Purple abrasive sheets and discs are available in a wide range of grits, in dust-free or no-hole configurations and in a variety of diameters to meet most sanding needs.

The spiral hole patter of 3M “Clean Sanding Discs” eliminates the need for painstaking aligment with the disc pad.

Noteworthy among the Purple Abrasives are 3M’s Clean Sanding Discs. Unlike other dust-free discs, these feature a spiral hole pattern that eliminates the need to exactly align the holes in the disc up to the holes in the disc pad—which can be irritating when you are trying to get though a big sanding project.

For fairing and shaping operations, Purple Abrasives are also available in “Long and Skinny” rectangular sheets to fit 3M’s Hand File or Hookit™ Marine Fairing boards. 3M rates their Purple abrasives “Best”.

Cubitron™ II Abrasives—Best of the Best

For the fastest-cutting, longest-lasting abrasives that money can buy, look towards 3M’s Cubitron™ II product lineup. 3M offers a full range of Cubitron™ II products, including sanding discs, cutting wheels, machine file belts and grinding discs. With advanced abrasive technology, these products utilize an abrasive material composed of electrostatically aligned, precision-shaped, triangular grains that act like individual cutting tools. As the abrasive wears, the grains shatter in a controlled fashion, resulting in fresh cutting edges and extended product life. Our Cubitron™ II product assortment is currently limited, but we will be expanding our offerings in the future.

Sanding Sponges

Foam sanding sponges are highly flexible abrasive pads that conform to curved surfaces. Choices include Sandblaster Small Sanding Sponges (3 ¾" x 2 ½") and Large Sanding Sponges (5 ½" x 4 ½” x ½"). Both conform to irregular surfaces. The most versatile are the Large Sanding Sponges, which can be folded to fit crevasses and will bend and twist to get into corners and other hard-to-reach areas—which makes them ideal for sanding the many odd nooks and crannies of boats. You can use them for sanding a wide range of materials, including wood, paint, and gelcoat.

Sanding sponges are available in a range of grits.

Match the Abrasive to the Job

The chart below calls out ten of the most common boat projects where abrasives are used. Pick the job and decide whether you’ll be sanding by hand or with a machine. From there we’ll recommend a product and range of grits. The experts at 3M recommend machine sanding, with an orbital or random-orbit sander, for most applications. Consistent pressure on the surface, along with uniform abrasion, provides a better finish using a machine.

Hand sanding is best when working on complicated shapes and delicate details. For example, you would hand sand when “breaking the edges” of a varnished or painted piece, taking care not to burn through the coating on the delicate corners.

Working Through the Grits

One question we get asked a lot is what grit to change to from the starting point. Our recommendations regarding the correct sandpaper grit to use are specific to each job and are taken from 3M, Interlux, Pettit and West System Epoxy publications. In general, do not start with too coarse of an abrasive, because you risk removing a lot of material, and leaving scratches that are too difficult to sand out. For coarser grits, from 80 to 320, the technicians at 3M recommend a jump of no more than a 100. In other words, start with 80 grit and follow with nothing finer that 180. For finer grits, 400 to about 1000, no more than a 200 jump.

This is a little different from the old-school approach we learned in boatbuilding and cabinet shops. We believed that the most effective progression was to sand through every grit—going from 80 grit to 100, 120, 150 and 180—sanding just enough with each one to remove the sanding scratches from the previous grit. We might still follow this approach when working on a special project, like a beautiful mahogany transom on a classic boat, but otherwise, we’ll follow the advice of the folks at 3M.

Your goal in sanding is to remove scratches on the surface created by the previous coarser grit. A couple bits of advice from Tom Burden, our colleague with custom cabinet shop experience:

Change to a fresh sheet of sandpaper more frequently than you think you should. A tired, clogged sheet won’t cut aggressively. The pros know that using a little more sandpaper is cheaper than paying workers to sand with a clogged sheet. For do-it-yourself boat owners, the question is, “How much is my time worth?”

When gluing, take care to remove excess glue from the surface before it dries. Carefully remove dried adhesive using a sharp chisel, not by sanding.

When sanding by hand, be sure you use very consistent pressure and also keep the paper or sponge clean. The increasing use of sanding sponges and Scotch-Brite pads has been great for most boat owners. They’re easy to clean, last a long time, come in commonly used grits and are great for many hand sanding applications.

Dust Removal

A vacuum system will contain most of the dust, but protective gear should still be worn.

Many machine sanders now have vacuum dust removal systems, and work with dust-free sandpaper discs that have holes in their surface. Many discs made by 3M are universal in application, and fit any of the name-brand orbital or random-orbital sanders. When changing to a finer grit of paper, make sure to clean off the dust and residue from the old, coarser sandpaper. Use a vacuum cleaner or use compressed air, if you have an exhaust system like that in a spray booth, to pull dust from the air. There’s little benefit in following your 80 grit sanding with 150 grit, and leaving the chunks of coarse abrasive on the surface!

For best results with a machine, don’t run with the whole sanding pad on the un-sanded surface. Overlap your sanding pattern by 50 percent on each pass and keep the paper clean.

Using Our Sandpaper Project Selector

Use the chart below to find your project, the suggested grit and the recommended product by color. As stated above, for machine sanding, red color is “Good,” the entry-level abrasive, followed by the Green and Gold “Better” products. Purple is the longest-lasting, sharpest cutting, “Best” abrasive. Those colors tie directly to the tables of abrasives that follow.