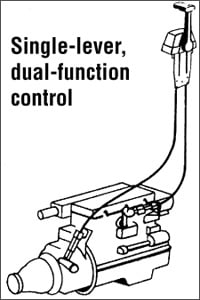

Dual-Function Controls

Dual-function mechanical controls are the most popular type of control in use today because they make boat handling easy. Both shift and throttle are operated by a single lever in a very instinctive action. Shifting is quick and can only be done at low rpm, which protects the engine's shift mechanism. Two cables are used: one for shift and one for throttle.

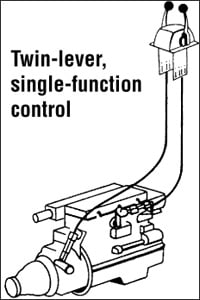

Single-Function Controls

On these controls one lever performs one function, either shift or throttle. The controls themselves may have one lever to control either shift or throttle, or two levers (one for the shift and one for the throttle).

Twin engine applications commonly use two two-lever single function controls. Both levers of one control operate the throttles, and the levers of the other control operate the shift mechanisms.

Multiple Station Installations

Dual- or multiple-station applications almost always use single-function two-lever controls. There are two basic systems recommended for multiple station installations. The choice is dictated by the sum of the degrees of bend in the cables. The fewer the bends, the more efficient the cable action. The control system that gives the fewest degrees of bend should be chosen.

The parallel control system is used when cable runs are relatively short and direct. It consists of cables from each control station running all the way to the clutch and throttle at the engine. An option with this system, for use when cable runs are long, difficult or would be too costly, is to run cables from the both controls to a transfer unit. Then single cables can be run from the transfer unit to the engine.

The recommended method, the series control system, runs cables from the upper station to the lower station controls. Then a second set of controls runs from the lower station controls to the engine.

Understanding Mechanical Advantage

Because you are using a lever to create motion at the other end of the control system (the throttle or shift mechanism on the engine), it requires less effort than if you were pushing directly on the engine's throttle or shift mechanism. Understanding the control's mechanical advantage and the amount of force needed at the engine is very important when specifying the correct control.

For example, if an engine requires 15lb. of force to move the shift lever, and you are using a control with a mechanical advantage of 2.5, you divide the force by the mechanical advantage to determine how much force must be exerted at the control lever to create the needed 15lb. of force.

15lb. / 2.5 mech. adv. = 6lb. of force required at the lever

Control Selection by Application

| Boat Type | Dual Function Top Mount | Dual Function Side Mount | Single Function Top Mount | Single Function Side Mount |

|---|---|---|---|---|

| Outboard and Sterndrive Single Station | • | • | • | |

| Outboard and Sterndrive Dual Station | • | |||

| Inboard Single Station | • | • | • | • |

| Inboard Dual Station | • | |||

| Jet Boats | • | |||

| Sailboats | • | • | ||

| Commercial | • | • | • | • |

The handle on Spinlock's ACTU Throttle Control Lever can be removed when it isn't in use.

ATCU Throttle Control for Sailboats

There is a very popular and hard-to-locate single lever, dual-function control that’s used on many inboard-powered sailboats. It’s made by Spinlock, a British supplier of high-quality rope clutches, offshore life jackets and other gear. The Spinlock ATCU is a conversion kit that works with SeaStar Systems throttles (sold separately). The ATCU/1 is designed to fit SeaStar models B700B, B80/S,C80/L,CH2100P and CH2600P. Available by Special Order, it is Model 10346344. We can also Special Order replacements for the removable handle, in case a member of your crew drops yours overboard. If this happens, any standard winch handle will fit the ACTU, allowing you to control your engine in a pinch.