A Harken Classic #48 winch with a 10" handle is a good fit for the 155% genoa on this Cal 40.

The modern sailboat winch dates from the 1960s, when two San Francisco Bay sailors who owned big racing boats named Baruna and Orient got together and founded the Barient Winch Company. The basic design of a winch has evolved little over roughly 50 years, but the major manufacturers, Lewmar, Harken, Andersen and Antal, have all recently introduced whole new product lines. These new winches are simpler to take apart and maintain, sometimes with no tools required. They come with cleverly engineered gripping surfaces on their drums, and they can be easily converted to powered electric operation. We'll walk you through what to consider when choosing winches for your sail boat.

- How Winches Work

- Do You Need a Self Tailing Winch?

- Choosing Power Ratio and Size

- Determining How Many Gears You Need

- Winch Materials

- Electrical vs. Hydraulic Powered Winches

How Sailing Winches Work

Winches allow you to exert force on lines by combining leverage, using a longer handle which turns a smaller diameter drum with ratchets to keep the drum from turning the wrong way, with gear reduction, as most winches have one or more gears. Winches with two, three or four gears let you tame sails that would otherwise be too hard to control.

With routine maintenance and a little care, they’ll last a very long time, which is why we see so many “plastic classic” boats in our marina that still have Barient winches from the 1970s. Sooner or later, replacing your old winches will become necessary, and the modern engineering of new winches makes sailing more fun.

Do You Need a Self-Tailing Winch?

Non self-tailing winches are less common today. They’re best for sportboats in applications that require constant trimming. For example, we use non-self-tailing winches to trim the asymmetric spinnaker on an Antrim 27, where the sheet is in constant motion, and we only use the winch in heavy winds.

Andersen #10 single-speed non-self-tailing winch. Andersen winches have stainless drums with their Power Grip Rib surface. The ribs generate horizontal friction on the drum, while allowing the line to move up and down easily.

Self-tailing winches: We recommend self-tailers for most other applications, especially when sailing short-handed because they make almost every job on board easier. Mount the stripping arm so that it points at the person grinding the winch, somewhere between the 5 o’clock and 7 o’clock positions.

Choose the Power Ratio and Size You Need

Most sailors can produce fifty pounds of tension or more on a line by pulling on it. When “jumping” a halyard, you can generally exert as much tension as your weight. But even with strong (or heavy) individuals, that amount of tension may not be enough. Large cruising and racing boats may have sheet loads in the 500 to 5,000-pound range, requiring us to multiply our otherwise inadequate strength. Therefore, we use winches to increase effectiveness.

Winches use both leverage (difference between the drum radius and the winch handle radius), and gear reduction (the number of times the handle turns for every rotation of the drum) to increase power. The combination of these two effects results in the Power Ratio, the theoretical mechanical advantage that comes from the gear ratio times the difference in the radii of the arcs that act on a line. We say “theoretical” because, as with almost everything mechanical, friction reduces overall efficiency.

Harken #40 Radial self-tailing chrome two-speed winch. Harken Radial Winches have angled ribs that drive the line down on the drum when you ease it.

Therefore, on a winch with a 10" handle length, 5" drum diameter, and a 6:1 gear ratio, the power ratio is (10/2.5) x 6=24:1. Higher numbers mean that your strength is multiplied more and that the line will come in more slowly.

Winch manufacturers publish sizing charts online and in catalogs that cross-reference winch size by sail area and type of application, so you can find the recommended size for a mainsheet, spinnaker halyard or other common use.

How Many Gears Do You Need?

One-speed winches: Turn one drum revolution for every handle revolution. Limited to small winches, these offer limited mechanical advantage. Least expensive of all winch types.

One-speed geared winches: The handle acts on the drum through a series of gears to increase mechanical advantage. The gear reduction allows the winch to exert more power than a non-geared winch. Handle ratchets when turned in the other direction.

Two-speed winches: Increase power available by changing speeds when the handle is rotated in the opposite direction. Turn the handle clockwise for a 1:1 gear ratio; turn it the other way for 5:1 or 6:1. A less expensive way of getting two power ratios in the same winch. NOTE: Jumps between first and second speed of 5:1 or 6:1 are generally considered too large, and two-speed winches are notorious for this.

Lewmar EVO® 40ST Self-Tailing Electric Winch can be serviced with no tools required. Size 40 and above convert to electric operation.

Two-speed geared winches: Use gear reductions in both directions. First gear might have a 2:1 ratio and second speed might be 7:1. First speed (the fast speed) can be either clockwise or counter-clockwise, so watch out.

Three-speed winches: Popular on big racing boats, expensive and complicated. Three speeds accommodate both fast trimming and high power ratios. A typical smaller three-speed winch, like the Harken 60.3ST, offers direct drive in first speed. The drum turns one revolution for each revolution of the handle, so under low loads, sheets can be trimmed very fast. While this speed is not geared, there is a slight mechanical advantage obtained from the relationship between the lever (handle) and the drum diameter.

Four-speed winches are typically three-speed winches that offer a choice of a direct drive first speed or a geared first speed. The crew selects the appropriate first gear and then uses the three speeds available. For example, in light air upwind, or for most spinnaker trimming, they might well choose a direct drive speed for very fast trimming, while for tacking in a breeze they would use the geared first speed.

Handle Length: Another way to increase the speed of a winch is to use a shorter handle, typically an 8" handle instead of a 10" handle. The 8" handle is faster because it swings in a smaller arc and a crew can rotate the handle faster.

Harken UniPower 900 electric winch has a very compact below-deck electric motor.

The same power problem is experienced, though, as handle length is a part of the power ratio calculation and decreasing the handle length 20% reduces power by 20%. Still, the 8" handle is a very effective and inexpensive means of increasing winch speed in light and moderate conditions.

Choose the Material

Anodized Aluminum: Lightest and cheapest, and reasonably long-lasting. Black color looks good on many boats but gets really hot in the tropics.

Chrome on Bronze: The durability of bronze with the good looks of chrome. Weighs up to 20% more than aluminum.

Bronze: Durable, long lasting, but requires frequent polishing to stay bright. Seen on traditional boats, but increasingly rare. Special Order only.

Stainless Steel: Expensive, but the most durable of any drum material. It looks great indefinitely. Andersen specializes in stainless steel.

Composite: Two types are available. Forespar makes a Marelon winch that is significantly lighter than bronze, less expensive and with no galvanic corrosion. Carbon fiber winches are a high-priced racing option.

Do You Want an Electric or Hydraulic Powered Winch?

Electric winches are becoming more popular because they make sailing less demanding by taking the grind out of trimming sails or jumping a halyard.

Andersen Compact Electric Winch has the motor located above the deck.

We’re also seeing more boats with hydraulic winches. All of our manufacturers are offering more choices with both modes of power. How do you select powered winches? Here are some questions to consider:

Power in only or power in-power out winches: Most electric winches grind the line in for you, and you ease as you would with a manual winch. Reversible winches, such as the Harken Rewind Radial, operate both ways. You don’t need to remove the line from the self-tailer. Harken’s winch is activated remotely by twin in/out buttons.

Motor placement: The main choice is whether you want above-deck or below-deck motor placement. Above-deck winches require less space under the deck and smaller holes to drill. Look for the Andersen Compact Electric Winches. There is also a great variety in sizes of below-deck motors. Harken’s UniPower 900 winches are the most compact if the winch is located on the cabintop and you need to preserve headroom.

How many amps does the winch draw? Electric winches use a lot of power, with motors commonly in the 700- to 2,000-watt range. Amp draws between 80A and 150A mean that you should consider these products as you would a bow thruster or electric anchor windlass. Do the math regarding the capacity of your house battery bank, so that you aren’t required to run your engine too frequently.

How do I determine my battery requirements? Calculate the amount of electricity you need for all the boat's systems per charging period. Compare this number to your battery capacity. For optimal battery life and performance, your battery capacity should be three times the daily draw. For example, if electrical draw is 100 amp-hours per day, you will need 300 amp-hours of battery capacity.

What is an amp-hour? How is it measured? Multiplying amps by hours of use yields the amp-hour (Ah) measurement. For example, an electric winch that uses 100A for 12 minutes (.2 hour) per charging period consumes 20Ah (100 x .2). To calculate your battery requirements, total this number with other systems on the boat.

How many amp-hours will an electric winch use per day? Winch amp-hours vary according to voltage, winch size, and the frequency of operation between charging periods. If you have a 24-volt system, you will use 30 to 35 amp-hours per day. With a 12-volt system, you will use 50 to 55 amp-hours. Larger winches - 66 and up - use 50 to 55 amps at 24 volts.

Should I have a separate battery for electric winches? No. It is best to have a bank of batteries to run your electrical components. A bank of batteries allows a slow draw from a large electrical supply and provides better battery performance. It's a good idea to install a separate battery system to start the engine to ensure enough power is always available.

Do I need anything else? You will need wire, two switches, a control box and a circuit breaker. We also recommend adding an optional load controller to protect your winches from overload. Match wire size to the size of the winch, system voltage, and wire length.

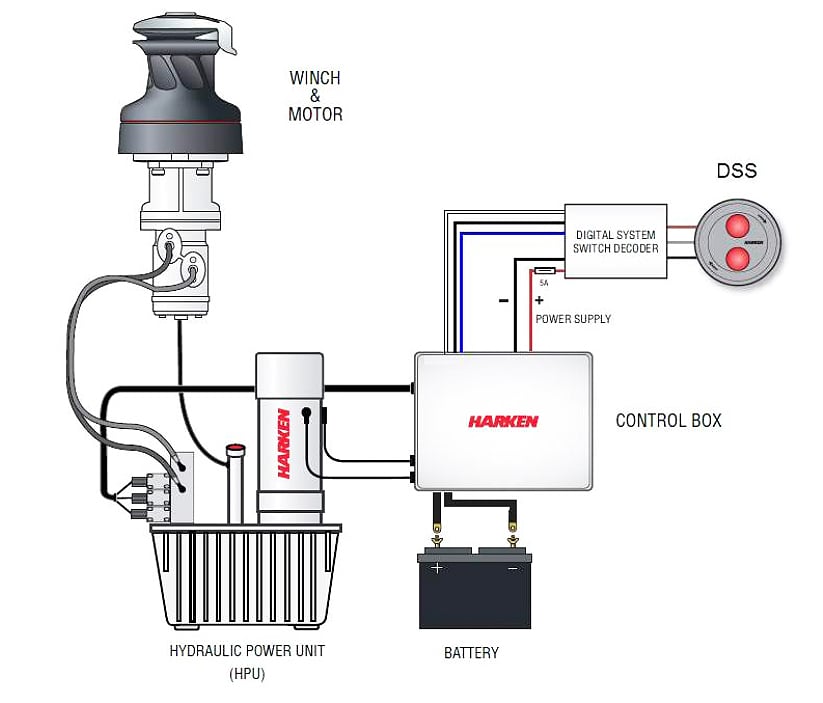

Hydraulic winches: These are big-boat (over 50') products that will require consultation with our winch suppliers. They’re installed as part of whole-boat hydraulic systems.