Inboard and sterndrive engines usually include a flexible impeller type raw water pump. Correctly installed, impellers may last for several years, but you should stick to a schedule of preventative instead of emergency maintenance. You should check the impeller’s condition during winterization and every 200 hours of operation.

Just the same, an impeller will eventually fail while in operation, and usually at an inconvenient time. That’s why you should carry a spare onboard, since the impeller is one of the vital components of your engine’s cooling system. Of course, you should also check the wet exhaust on your transom for the proper flow of cooling water each time you start the engine. We'll walk you through everything you need to find the right impeller and get it installed.

- Servicing the Pump

- Selecting the Right Impeller

- Impeller Material Types

- Checking Your Raw Water Strainer

Servicing the Pump

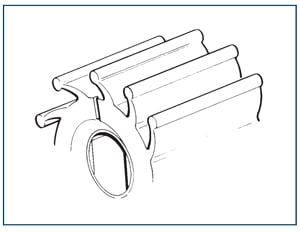

Checking the impeller is relatively simple. Close the thru-hull. Remove the three to six end cover screws and take off the cover and gasket. Take the old impeller out by gripping the hub of the impeller using channel lock or needle-nosed pliers. For easiest removal (or where the above tools don’t work) use an Impeller Puller Tool. Don’t use a screwdriver to lever it out, as this may score the soft bronze of the pump body and cause leaks. Some impellers are sealed onto their shafts with o-rings, a few (in some Volvo, Atomic Four and Universal engines) are held on with setscrews.

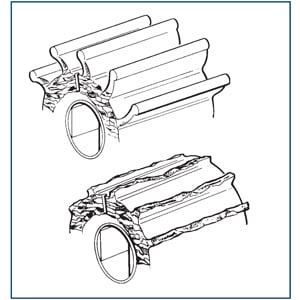

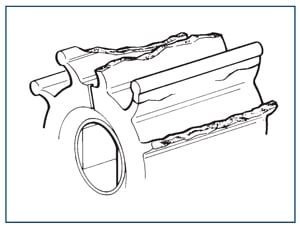

When the impeller is out, examine it closely. The tips of the vanes should be round, not flat, and there should be no cracked vanes or distortion in their shape. Check each vane by bending it. If the impeller is in pieces, be sure to get all the bits out and be sure they are all accounted for. Little chunks of rubber can migrate into the heat exchanger or the engine and cause overheating damage.

Troubleshooting 1

Symptoms: End faces hard and either polished or cracked, like carbon. Some or all blades completely missing.

Cause: Dry running, lack of water in pump. Temporary suction blockage. Leaking suction plumbing.

Remedy: Do not run pump for more than 20 seconds without liquid. Install a liquid sensor/temperature alarm. Check suction plumbing, strainers, and thru-hull fittings for blockages and leakage. Arrange discharge plumbing to trap liquid in the pump.

Troubleshooting 2

Symptoms: Blades have some or severe permanent set.

Cause: Normal use of impeller. Long term storage in pump. Normal end of impeller life.

Remedy: Replace impeller. Refit impeller to rotate in opposite direction. Remove impeller for long term storage.

Troubleshooting 3

Symptoms: Blades cracked about half way up the length. Some of blades missing. Reduced flow.

Cause: Normal end of impeller life.

Remedy: Replace impeller, check for impeller pieces in discharge plumbing.

Lightly lubricate the inside of the impeller housing with Vaseline to reduce the friction of the first dry startup. Use a heavy rubber band or loop of light line to collapse the impeller’s vanes, insert it, and pull the loop our with your pliers.

Some experts advise you to remove the impeller from the raw water pump, lubricate it with Vaseline petroleum jelly, and put it back in the pump. Then replace the cover to the pump housing, but leave the cover screwed in place loosely. This prevents the impeller from sticking to the pump housing. You can also remove the impeller until spring, so that its vanes do not “take a set.” Either way, leave an easy-to-see note to remind yourself to replace the impeller and/or tighten the cover in the spring.

Your pump may need additional service, particularly the seals, bearings, wear plates or clutch. Nigel Calder’s excellent book, Boat Owner’s Mechanical and Electrical Manual, covers detailed rebuilding. We highly recommend and use this book as a general reference source. If your pump is ready for replacement, most of the “classic” pumps from Jabsco, Sherwood and Johnson Pump are available.

Selecting the Right Impeller

We carry impellers from several manufacturers, including Johnson Pump, Mercury Marine, Sierra and Jabsco. There are several ways to determine the West Marine model number for a replacement Jabsco impeller:

- If you have a Jabsco pump, the Jabsco impeller part number can be found on the Data Sheet that came with it.

- You can also remove the impeller from the pump and then identify the Impeller Profile Code Letter by placing the impeller on the silhouettes that appear in the downloadable Jabsco Impeller Replacement Chart below. If your impeller matches one of the silhouettes, you can then measure the depth (See Chart A), identify the drive (See Chart B) and select the material.

- The correct Jabsco number for a replacement impeller can also be determined according to the number of blades, diameter (Dimension A), impeller depth (Dimension B) and shaft diameter (Dimension C). See the downloadable Jabsco Impeller Catalog below.

Neoprene, nitrile or polyurethane?

Use neoprene impellers for engine cooling, and for fresh and salt water transfer duties. Neoprene is suitable only for pumps where small amounts of oil or diesel fuel are present. Nitrile impellers are used for bilge pumping and for transfer duties where water is heavily contaminated, for example by oil or diesel. Polyurethane impellers are used for ballast pumps on boats that tow wakeboarders.

Check Your Raw Water Strainer

Now is a good time to check and clean your raw water strainer, since the thru-hull is closed. There are a number of styles, made out of plastic or bronze. Unscrew the cover and remove the filter basket, clean the basket, check the O-ring around the cover and reinstall. Now your raw water cooling system is ready for winter.